-

Your solutionsYour solutions

Jungheinrich Singapore: Material Handling Solutions

- Industries

-

Applications

-

Automation & Systems

Your solutions

-

Lithium-ion technology

Lithium-ion technology

Your solutions

-

Lithium-ion products

Lithium-ion products

Lithium-ion technology

-

Lithium-ion trucks

Lithium-ion trucks

Lithium-ion technology

-

Lithium-ion products

-

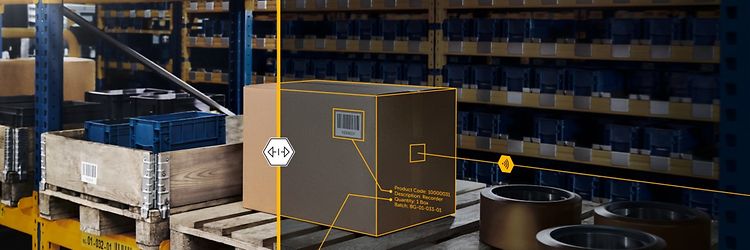

Digitalisation & Connectivity

Your solutions

-

Safety

-

Case studies

Your solutions

-

ProductsProducts

Jungheinrich Singapore: Material Handling Solutions

-

New Trucks

New Trucks

Products

- AntOn by Jungheinrich

- Forklift Hire

- Used Forklifts

- Automated Components

-

Batteries / charging technology

Batteries / charging technology

Products

-

Batteries

-

Charging technology

Charging technology

Batteries / charging technology

-

Batteries

- Racking / warehouse storage

-

Digital Products

-

Special Builds

Products

- Radio data transmission

-

Operating Manuals

Products

-

New Trucks

-

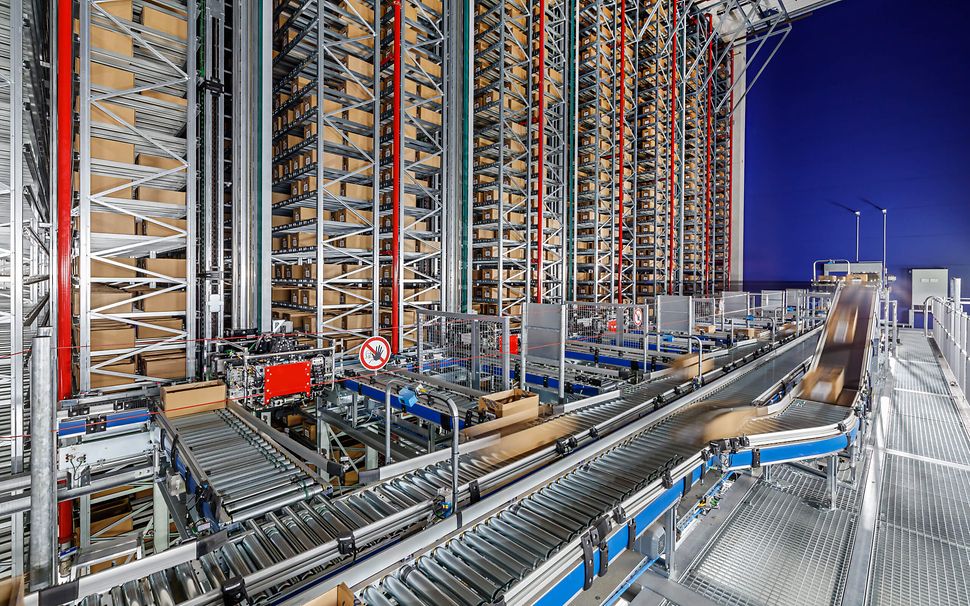

Automation & SystemsAutomation & Systems

Jungheinrich Singapore: Material Handling Solutions

-

Consulting warehouse optimization

Automation & Systems

-

Mobile Robots

Mobile Robots

Automation & Systems

-

Storage systems

- Digital products and software solutions

-

Consulting warehouse optimization

-

ServicesServices

Jungheinrich Singapore: Material Handling Solutions

- Rental

-

Jungheinrich spare parts

Services

- After Sales Services

-

Energy management

Services

-

Automatic systems

Services

-

Operating manuals

Services

-

About usAbout us

Jungheinrich Singapore: Material Handling Solutions

-

Jungheinrich Singapore

About us

- Innovation & Aspiration

- Sustainability

- Stories

- Innovation & Aspiration

-

Press / Events

About us

-

Certificates

About us

-

Location finder

About us

-

Jungheinrich Singapore

-

Career

-

Online Shop